Current good manufacturing practice (cGMP) is a set of regulations instituted and enforced by the U.S. Food and Drug Administration (FDA) that “assure proper design, monitoring, and control of manufacturing facilities and establish minimum requirements for any manufacturing process.” When a company is following cGMP standards it assures “identity, strength, potency, and purity of drug products” follow the current FDA regulations. GMP standards ensure that biotech and pharmaceutical companies are conducting their manufacturing activities with quality of product as a focus, so that consumers receive the same high-quality product every single time.

In a complex and growing market, CDMOs can help streamline the demand for cell therapy manufacturing, and with cGMP regulations and standard in mind, OrganaBio’s 19,000 square foot, state-of-the-art, cGMP facility that’s located in Miami, Florida, is designed to manufacture cellular raw materials for immunotherapy development and offers industry partners clinical support services to rapidly manufacture therapeutic materials.

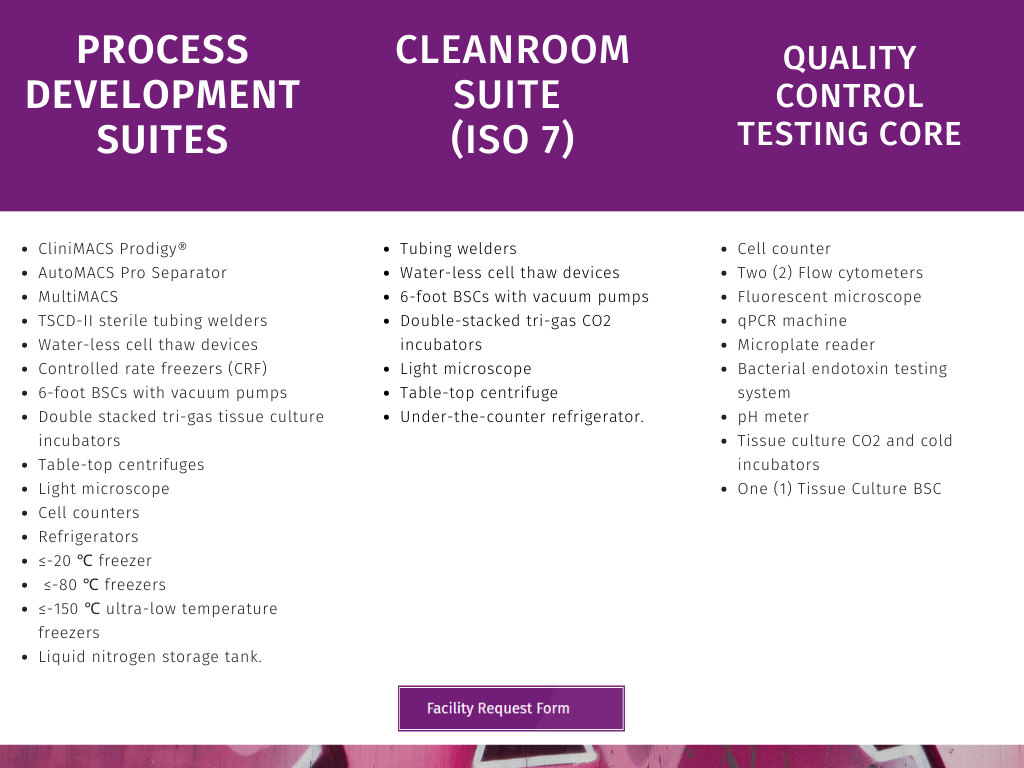

The OrganaBio cGMP facility includes advanced process development suites, ISO 7 cleanrooms, and a quality control testing core, all equipped with qualified and validated scientific equipment. The host of support services offered, include material receipt, inventory management, ambient and cold storage, a Part11 compliant and validated environmental monitoring, two back up generators designed to power the entire facility and all equipment, and facilities maintenance. The facility manufacture, store, and distribute human cellular therapy products for clinical development.

All OrganaBio processes are governed by standard operating procedures (SOPs) and Master Batch Records to ensure consistency, traceability, and readiness for tech transfer. Materials used in processes are released, traceable, and verified to be tested/inspected in accordance with approved specifications-, procedures-, and internal-SOPs, as well as supplier Certificate of Analysis (CoA) requirements. When the required steps within the CoA requirements are completed, and the manufactured products meet the rigorous standards put forth by the FDA, the final product release procedures are completed by OrganaBio’s qualified, trained Quality Assurance personnel. As defined by the FDA in 21 CFR Part 210 & 211 (cGMP in Manufacturing, Processing, Packing, or Holding of Drugs and Pharmaceuticals), 21 CFR Part 600, 601 & 610 (Regulations for Biologics), 21 CFR Part 1271 (Regulations for Human Cells, Tissues, and Cellular and Tissue-Based Products), and 21 CFR Part 820 (Quality System Regulation), OrganaBio ensures its product safety, quality, purity, potency and effectiveness.

From development and manufacturing to commercialization of cell therapies and other advanced therapies, OrganaBio’s team of industry veterans brings decades of experience to bear on processes, anticipate potential issues, and navigate regulatory hurdles to facilitate the rapid translation of novel technologies into clinical applications.

Knowing how quickly technologies evolve, OrganaBio’s cGMP manufacturing facility has also adopted the following features and equipment within its Process Development Suites, Cleanroom Suite and Quality Control Testing Core to reassure biotech and pharmaceutical companies receive a consistently high-quality product with an opportunity to scale.

Ask about our recently opened Southern California (Irvine, CA) cell processing hub by scheduling a meeting with our Regional Scientific Sales Director, Marisa Reinoso or reach out to our Sales team at [email protected].